Nylon mesh conveyor belts are an important part of many industrial operations, and proper maintenance is essential to ensure optimal performance. To ensure that your nylon mesh conveyor belt is running at peak performance, it is important to take the following steps:

1.Regularly inspect the belt for signs of wear. Look for any tears, fraying, or loose threads in the mesh. If any of these signs are present, it is important to replace the belt as soon as possible to avoid further damage. If you are looking for the best nylon mesh conveyor belts then, you may visit this website.

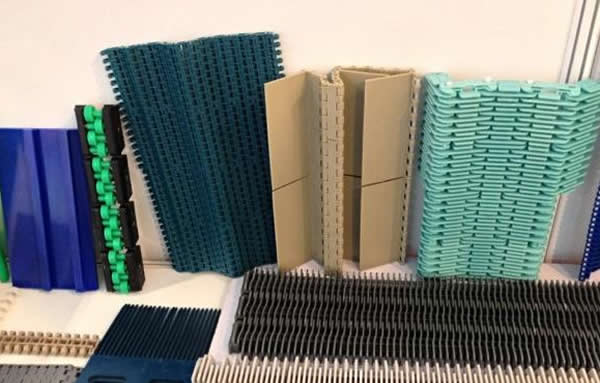

Image Source: Google

2.Clean the belt regularly. This can be done with a vacuum cleaner, a soft brush, or a damp cloth. Dirt and debris can cause the belt to become worn or frayed over time, so it is important to keep it clean.

3.When replacing a belt, ensure that the new one is the same size and type as the old one. Different sizes and types of belts can cause the conveyor system to become misaligned, leading to reduced performance.

4.Ensure that the tension on the belt is properly adjusted. Too much tension can cause the belt to stretch and wear out quickly, while too little tension can cause the belt to slip and decrease performance.

5.Lubricate the conveyor system regularly with a suitable lubricant. This will help to reduce friction and wear on the belt, and ensure that the conveyor system is running at peak performance.